The world is on the edge of a technological revolution that can fundamentally change the ways in which businesses work, communities are developed and people interact with each other. The breakthroughs in technology are occurring at exponential rates since the AI systems, communication networks and IoT aspects are evolving. Today, the boundary between the physical world and the digital world has been blurred to a greater extent. The powers of Artificial Intelligence (AI), IoT, robotics, quantum computing and genetic engineering have been fused to create a digital world, and this is what we call a Fourth Industrial Revolution. The interchangeable term for the fourth industrial revolution is industry 4.0, which usually represents the smart machines of industrial value. The evolution of industry 4.0 is not possible without the occurrence of communication between the network of sensors or in short, IoT. IoT is indeed fueling the fourth industrial revolution and the following article discusses how this is happening.

What is Industrial Revolution and How It Started?

In modern history, the industrial revolution is referred to as the process of shifting the handicraft economy to the one dominated by machines in manufacturing. The First Industrial Revolution started in 1760 and ended in 1840. In this revolution, hand production was completely shifted to machines. Between 1871 and 1914, the Second Industrial Revolution took place and in this revolution electricity was introduced along with the installation of telegraph networks and extensive railroads. This enabled faster communication and travel for people. The Third Industrial Revolution is also referred to as the digital revolution which occurred in the 20th century. Extensive use of information technology, digital electronics and computers was observed in this revolution for automating industrial procedures. In all these revolutions, humans observed that the probability of errors in work has been reduced significantly along with the minimized labour which has ultimately helped industries in reducing operational expenses. This is why the Fourth Industrial Revolution is taking place with internet connected technologies. The technologies in this revolution include AI, robotics, big data, cloud computing and of course, IoT. This technological advancement is on the edge of greatly impacting the economies and industries as well as the lives of the people. Just like the previous technological revolution, this will also lead to significant shifts in society.

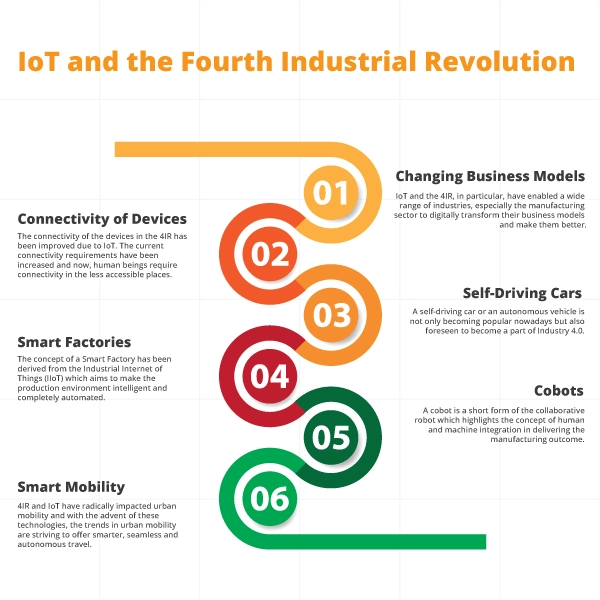

IoT and the Fourth Industrial Revolution

Changing Business Models

IoT and the 4IR, in particular, have enabled a wide range of industries, especially the manufacturing sector to digitally transform their business models and make them better. From providing a managed service to selling a product, every aspect is covered by IoT in industry 4.0. With the help of IoT, the products are transformed into an asset which can be monitored remotely by connecting them to the internet. This facilitates companies in understanding the use of their assets along with predicting the maintenance. By having the information beforehand about faults in the system, the managers can take appropriate actions to minimize the drastic impact. Based on the reliable data gathered and analyzed through IoT, companies can better understand the risk and financial exposure, furthermore, they can even establish service-based contracts with service-level agreements.

Connectivity of Devices

The connectivity of the devices in the 4IR has been improved due to IoT. The current connectivity requirements have been increased and now, human beings require connectivity in the less accessible places. For instance, on construction sites, rural fields and remote locations or potentially everywhere. However, with IoT, we are now enabled to use power-efficient sensors, cloud-based analytics, 4G and 5G cellular networks. The report published by Statista forecasted that by 2030, there will be more than 50 billion devices connected ranging from smart industrial machines to kitchen appliances. This indicates that a lot of data will be gathered through these interconnected devices and stored in the centrally or regionally localized data storage. The analyses of the collected data can help in identifying the users’ preferences, behavior, risk patterns and product usage which can enable the companies in improving their products or services accordingly.

Self-Driving Cars

A self-driving car or an autonomous vehicle is not only becoming popular nowadays but also foreseen to become a part of Industry 4.0. Self-driving cars are equipped with a wide range of IoT sensors which sense the surroundings and after analyzing the collected data and enable the car to act accordingly. Great potential is also being promised by the application of technologies developed for self-driving cars from public transportation to private site material handling. These self-driving cars not optimize the safety of the people and cost, but also hold the potential to reduce the damage to the goods. The future of transportation and logistics is found to be self-sustainable within industry 4.0.

Smart Factories

The concept of a Smart Factory has been derived from the Industrial Internet of Things (IIoT) which aims to make the production environment intelligent and completely automated. In smart factories, all of the production procedures take place and are managed without any human intervention. All the operations in the smart factories are powered by IoT, AI and data analytics etc., and happen due to the exchange of data between the technology elements. This makes the operations more efficient than ever along with saving the operational cost. To a greater extent, the smart factory solutions are associated with the manufacturers, who want to utilize their resources to the fullest, increase the productivity of the workers and reduce delays to retain their competitive advantage. This indicates that the smart factories are reducing man-to-machine cooperation and making the industrial procedures as smooth as possible.

Cobots

A cobot is a short form of the collaborative robot which highlights the concept of human and machine integration in delivering the manufacturing outcome. The fourth Industrial Revolution is all about automation and these cobots are specifically designed to work simultaneously with humans, operating systems and fellow machines to deliver the most productive outcomes. Industry 4.0 cobots are movable, lightweight and have far better capabilities as compared to their predecessors. Cobots are now referred to as the physical or hardware version of augmented intelligence as the previous systems are confined to the software. The abilities of cobots demonstrate the best in AI-assisted intelligence along with maximizing human capabilities, and this is undoubtedly the most notable breakthrough of the 4IR.

Smart Mobility

4IR and IoT have radically impacted urban mobility and with the advent of these technologies, the trends in urban mobility are striving to offer smarter, seamless and autonomous travel. Many cities around the globe are focusing on smart mobility solutions for their smart city developments. Currently, 4IR is bringing the four most important trends in mobility. These include smart payment (carless and cashless), smart booking system, smart multichannel customer service and smart mobility infrastructure. The fourth Industrial Revolution is powered by IoT, AI and ML and this is turning the idea of futuristic mobility into reality making the travel of the tech-savvy commuter extremely productive and secure.

Conclusion

From the aforementioned discussion, it can be concluded that the IoT and 4IR go hand in hand with each other when it comes to technological progression which humans have never seen before. With the overall aim of making people’s lives easier 4IR has blended the physical and virtual world for good. Undoubtedly, advancement in technology, data processing, automation and robotics, the IoT has imposed a dramatic impact on the Industry 4.0 or 4IR and it will continue to evolve in 2022 and beyond.